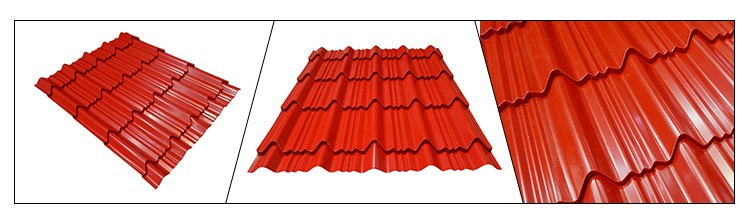

Product Description

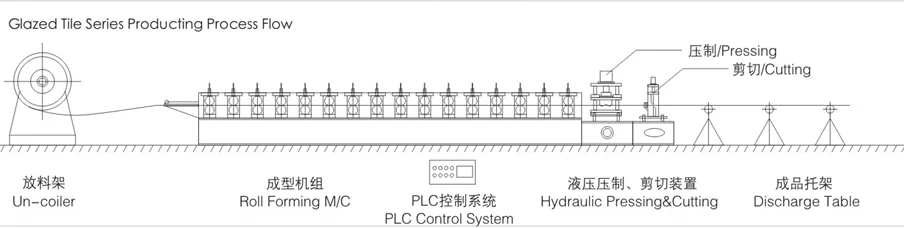

| Specifications for Circular Arch Glazed Tile Steel Making Machine | |||

| coil material | type | Colored Steel Plate, Galvanized Board, Aluminum Plate | |

| width | 1000mm/1200mm (according to customer requirements and profile drawing) | ||

| thickness | 0.3-0.8mm | ||

| manual decoiler | outside diameter | 1250mm | |

| inside diameter | 500-508mm | ||

| coil width | 1300mm | ||

| coil load | 5T | ||

| forming device | shaft material | 45#steel-high quality steel, diameter 70 mm | |

| roller material | 45# steel with chrome coating | ||

| roller station | depends on final design | ||

| Main frame | 300/350 H steel | ||

| chain transport | 1" | ||

| board thickness | 16mm | ||

| weight | around 5T(depends on final design) | ||

| dimension | 6500mm*1300mm*1100mm(depends on final design) | ||

| control system | PLC control system | ||

| total power | 5.5+4kw (depends on final design) | ||

| voltage | 380V,50HZ,3 phascs or as your need | ||

| productivity | 0-4m/min(depends on final design) | ||

Delivery Time:

within 45 days after receipt of buyer's deposit

a. Two decades professional cold steel forming equipments manufacturer

Main products: glazed tile Roll Forming Machine, Ridge Cap Roll Forming Machine, corrugated roll Forming Machine, most popular color steel roll forming machine, double deck color steel Roll Forming machine, keel roll forming machine, C/Z purlin forming machine, Austalia style roller shutter door forming machine and etc.

b. National GB/T, CE and ISO9001:2008 standard

c. Relationship with customers from more than 30 countries and areas

Circular Arch Glazed Tile Steel Making Machine

Q: Does one machine can only produce one style panel profile?

A: Not exactly. For wider and double layer making machine. It can produce more than 6 kinds of panels.

Q: Do you sell only machines of fixed specification?

A: No, most of our machines are built according to customers' specifications, using top brand components.

Q: What size of decoiler can you supply us with?

A: From 5-ton decoiler to a 25-ton motorized Hydraulic Decoiler

Q: How to visit your company?

A: a.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour), then we can pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

Q: What can you do if the machine broke down?

A: Our machine's warranty period is 12months. If the broken parts can't be repaired, we can send the new parts to replace the broken parts for free, but you need to pay the express cost yourself. if after warranty period, we can solve the problems through negotiation, and we will supply the technical support for the whole life of the equipment.

Product Categories : Roof Tile Roll Forming Machine > Glazed Roof Tile Roll Forming Machine