Find Forming Machine, Metal Forming Machine, Roof Tile Forming Machine on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

| Delivery Time: | 60 Days |

|---|

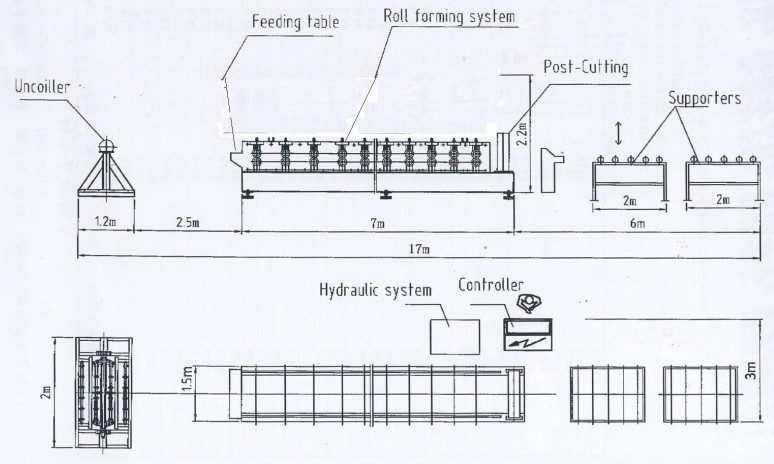

Model No.: bl-16-25

| Material thickness | 0.3~0.7mm |

| Material yield stress | 230~550 Mpa |

| Max. forming speed | 8~25m/min |

| Roller material | 45# steel with chrome treatment |

| Roller driven type | Chain transmission |

| Controller & operation | PLC & touch screen and button |

| Hydraulic system pressure | 12 Mpa |

| Hydraulic station motor power | 3 Kw |

| Main motor power | 4~5.5Kw |

| Total power | 7~8.5Kw |

| Total weight | About 6000~8000 Kgs |

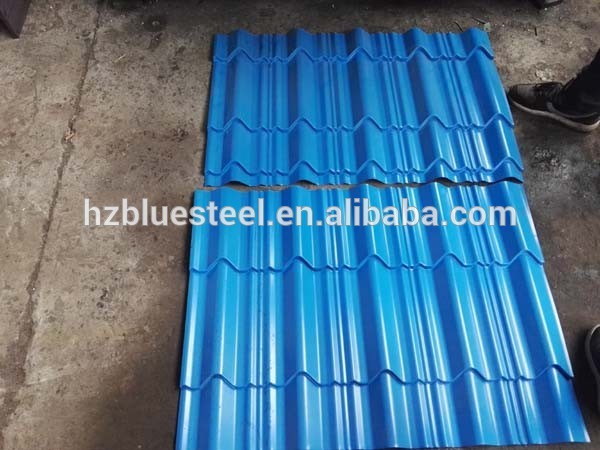

Main Features 1.Our machines can uses galvanized steel sheet, colored armor plate or

Main Features 1.Our machines can uses galvanized steel sheet, colored armor plate or Machine Parts Name: PLC Control Brand: Mitsubishi Original: Japan The system uses modularized structure and has convenient, reasonable, canonical wiring arrangement, and its maintenance is quite easy. The independent operating console facilitates the mutual dialogue between the operator and the machine. The operation is easy and steady and can be choosed operation by manual or automatically.

Machine Parts Name: PLC Control Brand: Mitsubishi Original: Japan The system uses modularized structure and has convenient, reasonable, canonical wiring arrangement, and its maintenance is quite easy. The independent operating console facilitates the mutual dialogue between the operator and the machine. The operation is easy and steady and can be choosed operation by manual or automatically.  Main Parts Name: Decoiler

Main Parts Name: Decoiler

Machine Parts Name: Safety Cover & Auto Stacker

Machine Parts Name: Safety Cover & Auto Stacker Application

Application  Our Service

Our Service

Pre-Sales Service * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service

Pre-Sales Service * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service

| Packaging | |

| Product | |

| Weight | 8000kg |

| Packaging Details | 1. One 40ft container for loading one set machine with manual decoiler; 2. The whole Wiped Anti Rust Oil, PLC controller covered by foam film; 3. Spare parts and some small parts packed in plastic tooling box; 4. All Components Fixed by steel wire with Container. |

| Packaging | |

| Product | Roof Tile Roll Forming Machine |

| Weight | 8000kg |

| Packaging Details | 1. One 40ft container for loading one set machine with manual decoiler; 2. The whole Wiped Anti Rust Oil, PLC controller covered by foam film; 3. Spare parts and some small parts packed in plastic tooling box; 4. All Components Fixed by steel wire with Container. |

Workshop Showroom

Workshop Showroom

Products Name with link 91.8% Response Rate Products Name with link 91.8% Response Rate Products Name with link 91.8% Response Rate Contact us if you need more details on Metal Tile Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Glazed Tile Roll Forming Machine、Hydraulic Roof Cold Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Products Name with link 91.8% Response Rate Products Name with link 91.8% Response Rate Products Name with link 91.8% Response Rate Contact us if you need more details on Metal Tile Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Glazed Tile Roll Forming Machine、Hydraulic Roof Cold Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Step Tile Forming Machine